Unlocking the Secrets: Processing and Manufacturing of New Precious Metal Materials

Introduction

Have you ever wondered about the dazzling world of precious metals? From gold to platinum, these materials are not only stunning but also incredibly valuable. In today’s fast-paced market, the processing and manufacturing of new precious metal materials has become a hot topic. Let’s dive into some common questions, clear up the confusion, and uncover what makes these materials so special.

What Are Precious Metal Materials?

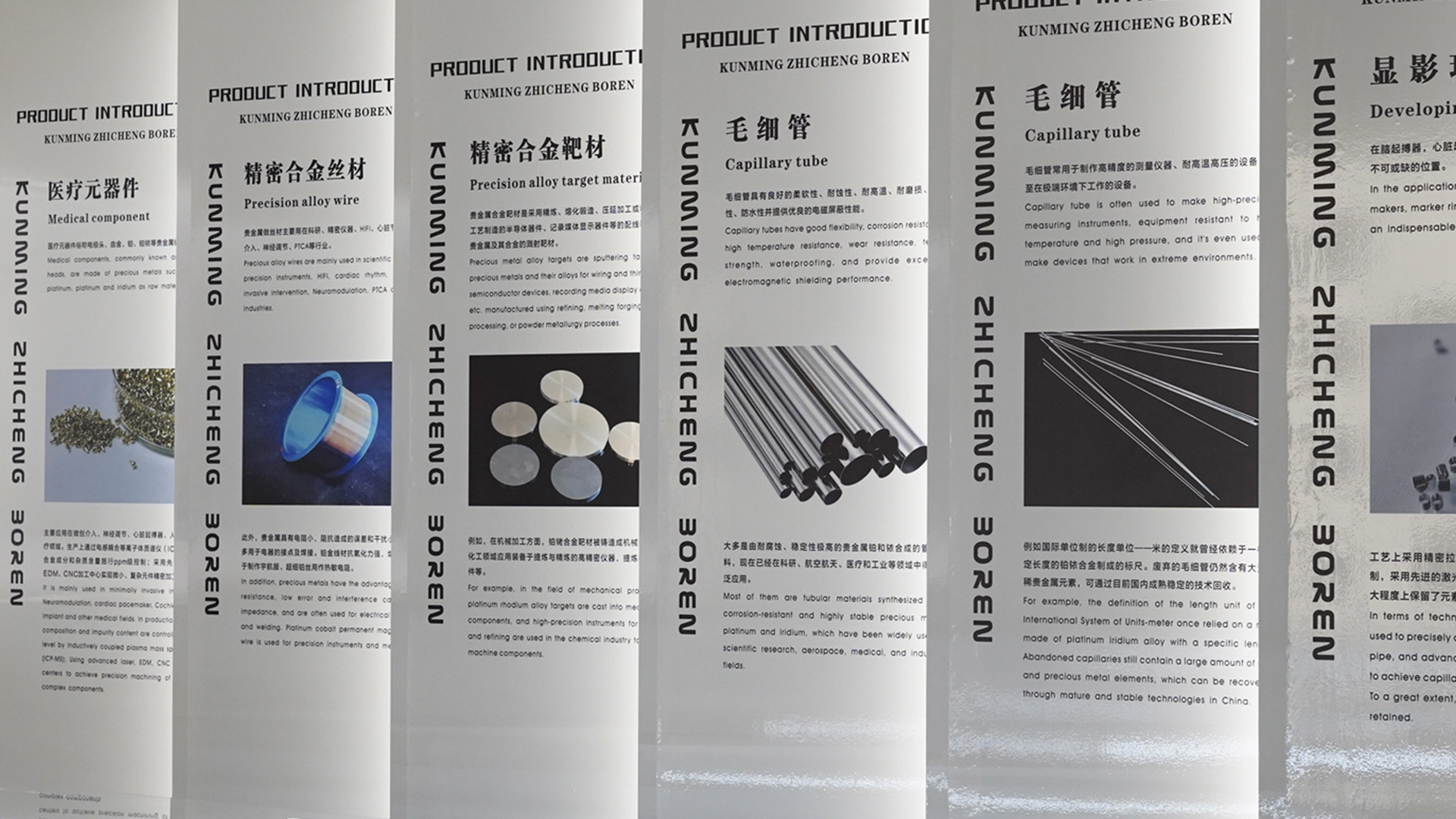

First things first—what exactly are these precious metals? Well, they are rare, naturally occurring metallic elements that hold significant economic value. Think of them as the rockstars of the metal world! Gold, silver, and platinum often take the spotlight, but there are newcomers on the scene, too. With the rise of technology and innovation, new alloys and materials are being developed, changing the game.

Why Are New Precious Metal Materials Important?

Now, you might be asking yourself, why bother with new materials? The answer is simple: adaptability and sustainability! As industries evolve, so do their needs. New precious metal materials can lead to enhanced performance in electronics, improved durability in jewelry, and even applications in medicine. It’s all about finding that perfect balance between functionality and beauty.

How Are These Materials Processed?

Processing precious metals isn’t just about melting them down and shaping them into something new. Oh no! It’s a complex dance of science and art. The processing and manufacturing of new precious metal materials involves several stages:

- Extraction: The first step is to extract the raw material from the earth. This can involve mining or recycling old materials.

- Refining: Once extracted, the metals need to be refined to remove impurities. This is where the magic happens!

- Alloying: Different metals are combined to create alloys that have specific properties. Think of it as mixing paint to get just the right color.

- Fabrication: Finally, the materials are shaped into their final form through processes like casting, forging, or machining.

What Are Common Challenges in Processing?

Like any industry, theprocessing and manufacturing of new precious metal materialscome with their own set of challenges. Some of the most common issues include:

- Cost: Precious metals aren’t cheap! The cost of extraction and refining can be astronomical.

- Environmental Impact: Mining can have devastating effects on the environment if not done sustainably.

- Market Fluctuation: Prices can soar or plummet based on demand, making it a tricky business.

What’s Next for Precious Metals?

The future looks bright for theprocessing and manufacturing of new precious metal materials With advancements in technology, we can expect to see more innovative applications, eco-friendly practices, and perhaps even new materials that we haven’t even dreamed of yet! The industry is constantly evolving, and staying on top of trends is crucial.

Conclusion

In a nutshell, precious metals are more than just shiny objects; they are vital components in various industries. Understanding the processing and manufacturing of new precious metal materials can open doors to endless possibilities. Whether you’re a curious enthusiast or a seasoned professional, there’s always something new to discover. So, keep your eyes peeled, because the world of precious metals is just getting started!

Previous Page: