Navigating the Nuances: Processing and Manufacturing of New Precious Metal Materials

Introduction: A Shiny Opportunity

When it comes to the world of precious metals, the processing and manufacturing of new precious metal materials can seem as intricate as a Swiss watch. But fear not! If you’re looking to dive into this shimmering realm, you’re in for an enlightening journey. Whether you're a seasoned pro or a curious newbie, understanding the ins and outs of this industry is crucial.

Understanding Precious Metals

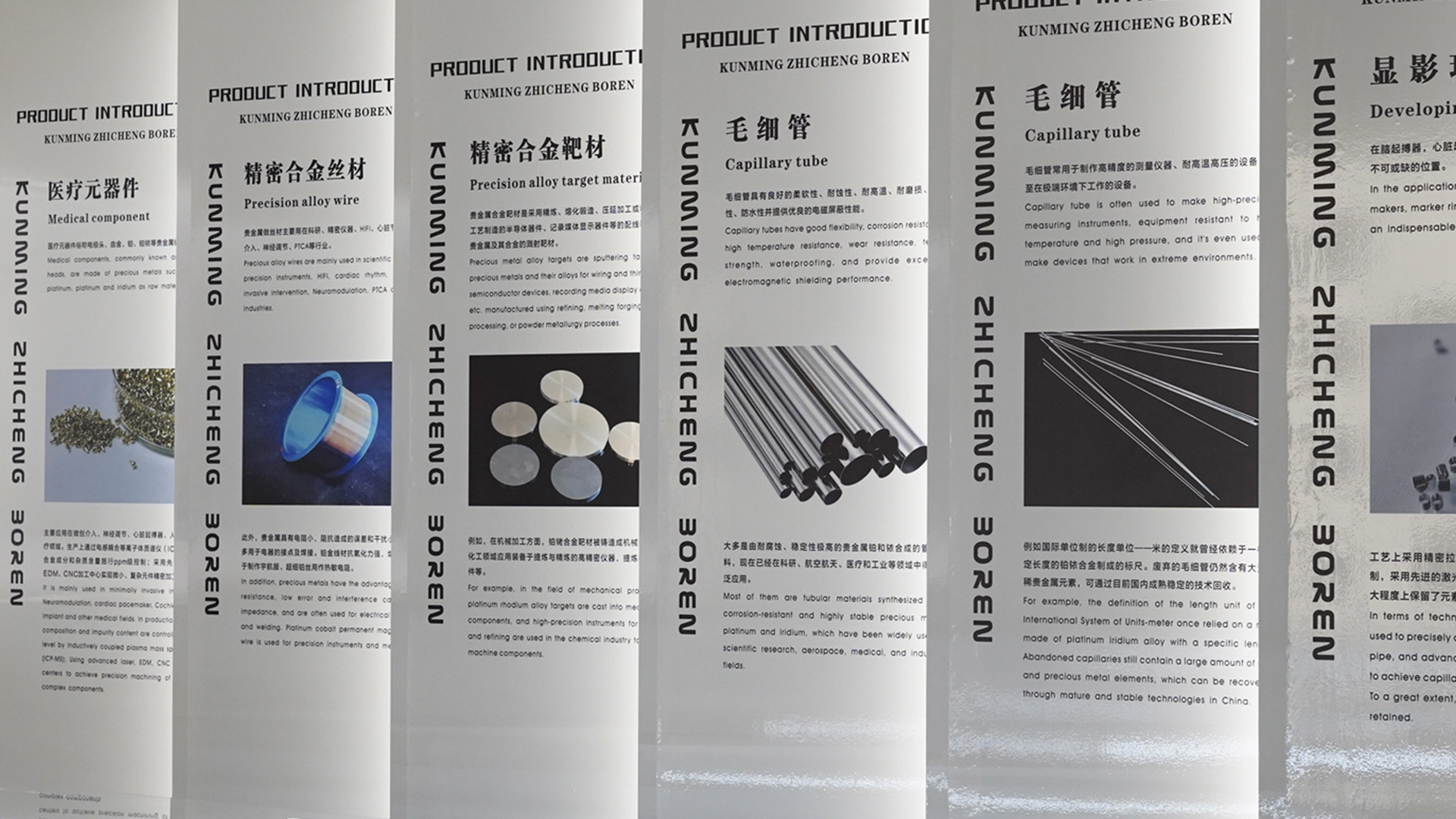

Precious metals, like gold, silver, and platinum, have captivated humanity for centuries. But with the emergence of new materials, like palladium or rhodium alloys, the landscape is changing. The processing and manufacturing of new precious metal materials not only involves the extraction and refinement of these metals but also their innovative applications in various sectors including electronics, jewelry, and even renewable energy technologies.

The Processing Stage: It’s All in the Details!

So, what does the processing stage entail? Well, it’s a bit of a dance, involving several steps:

- Extraction: The first step is to extract precious metals from ores. This can be done through mining or recycling old products.

- Refinement: Next up is refining these metals to remove impurities. This is where chemistry comes into play, utilizing methods like electrolysis or chemical leaching.

- Alloying: After refinement, metals are often alloyed to enhance their properties. This step is key when processing and manufacturing new precious metal materials.

Each of these stages requires a keen eye for detail and a solid understanding of material properties. Remember, one misstep can lead to costly waste!

Manufacturing: Turning Metal into Magic

Once the processing is done, it’s time for manufacturing. Here’s where creativity meets technology. The manufacturing of new precious metal materials can involve:

- Machining: This involves shaping metals into desired forms using tools like lathes and milling machines.

- 3D Printing: A game-changer in the industry! This technology allows for intricate designs that were once thought impossible.

- Finishing: Lastly, the finishing touches—polishing, plating, and coating—give the metal that eye-catching sheen.

Each method carries its own set of considerations, especially when it comes to cost and time efficiency. You’ve gotta weigh your options carefully!

Key Considerations: What to Keep in Mind

Now, let’s get to the nitty-gritty. Here are some crucial points to consider when entering the world of processing and manufacturing of new precious metal materials:

- Quality Control: Regular checks are a must. Keeping standards high ensures that you're producing top-notch materials.

- Environmental Impact: Be mindful of how your operations affect the planet. Sustainable practices are not just trendy; they’re essential.

- Market Trends: Stay updated on what’s hot and what’s not. The precious metals market can be volatile, and being in the know can give you a leg up.

In short, knowledge is power! The more informed you are, the better your chances of success.

The Future: A Bright and Gleaming Path

As we look ahead, the processing and manufacturing of new precious metal materials will likely evolve with advancements in technology. Innovations like AI and automation are already making waves, streamlining processes and reducing costs. It’s an exciting time to be a part of this industry!

Conclusion: Shine On!

To wrap things up, diving into the processing and manufacturing of new precious metal materials is no small feat. However, with the right knowledge, attention to detail, and a little bit of creativity, you can navigate these sparkling waters. So, gear up, stay informed, and let your passion for precious metals guide you to success!

Previous Page: